Coffee roasting is where science meets art. This transformative process takes the humble green coffee bean - which is grassy, dense, and essentially undrinkable - and turns it into the complex, aromatic delight we all know and love. Understanding the roasting process can deepen your appreciation for your daily cup and help you identify the roast profiles that best suit your taste preferences.

The Green Coffee Bean

Before diving into the roasting process, it's worth understanding what we're starting with. Green (unroasted) coffee beans are the seeds of the coffee cherry, which have been processed, dried, and had their protective parchment layer removed. These beans contain:

- Complex carbohydrates and sugars

- Proteins and amino acids

- Lipids (oils)

- Acids (chlorogenic, citric, malic, etc.)

- Moisture (typically 10-12%)

- Hundreds of volatile compounds

While these components exist in the green bean, many are bound in complex structures that need heat to break down and transform into the flavors we recognize as coffee.

The Science of Coffee Roasting

When green coffee beans enter the roaster, a series of chemical reactions occur as the temperature rises. Understanding these stages helps explain how different roast profiles develop:

Drying Phase (Up to 160°C/320°F)

The first phase of roasting is primarily about driving moisture out of the beans. During this stage:

- Beans turn from green to yellow

- Water evaporates (beans lose 10-12% of their weight)

- The beans absorb heat energy but haven't yet begun major chemical changes

- A grassy, hay-like smell is emitted

Maillard Reaction (160-190°C/320-375°F)

Named after the French chemist who first described it, the Maillard reaction is the critical flavor-developing stage where amino acids and reducing sugars interact, producing hundreds of new compounds. This is the same reaction that gives bread crust, seared steak, and toasted marshmallows their characteristic flavors.

- Beans turn increasingly brown

- Complex aromatic compounds develop

- Sugars begin to caramelize

- The bean structure begins to expand

First Crack (Around 196-205°C/385-400°F)

"First crack" is an audible popping sound (similar to popcorn) that signals a significant milestone in the roasting process. This occurs when:

- Internal bean pressure reaches a breaking point

- Cellulose structure fractures

- Bean volume increases by 50-100%

- CO₂ and water vapor are forcefully released

First crack marks the beginning of light roast territory. From this point forward, the roaster's skill and timing become increasingly crucial in determining the final flavor profile.

Development Phase (Post-First Crack)

After first crack, the roaster carefully controls the rate of development to achieve the desired roast level:

- Acids begin to break down

- Body-contributing compounds develop

- Sugars continue to caramelize

- Oils may begin to migrate to the surface

Second Crack (Around 225-230°C/435-446°F)

If roasting continues, a second series of cracks (more subtle than the first) signals the beginning of dark roast territory:

- Cellular structure further breaks down

- Oils rapidly migrate to the surface

- Smoky flavors develop

- Sugar carbonization (burning) begins

Roasting is a balance of art and science. The difference between a transcendent coffee and a mediocre one can be a matter of seconds in the roaster.

Roast Profiles and Their Flavor Characteristics

The point at which the roaster decides to end the process dramatically affects the coffee's flavor profile. Here's how different roast levels generally present in the cup:

Light Roasts (City, Cinnamon, New England)

Ending Temperature: Just after first crack (385-410°F/196-210°C)

Appearance: Light brown, no oil on surface, pronounced origin characteristics

Flavor Profile:

- High acidity (brightness)

- Floral, fruit-forward notes

- Complex, nuanced flavors

- Lighter body

- Higher caffeine content

Best For: Single-origin coffees with distinctive terroir, pour-over and filter brewing methods

Medium Roasts (American, Breakfast, City+)

Ending Temperature: Between first and second crack (410-430°F/210-221°C)

Appearance: Medium brown, may have small spots of oil, balanced appearance

Flavor Profile:

- Balanced acidity and body

- Caramel sweetness emerges

- Origin characteristics still present but moderated

- More rounded flavor profile

Best For: Versatile everyday drinking, good for most brewing methods

Medium-Dark Roasts (Full City, Vienna)

Ending Temperature: Beginning of second crack (430-445°F/221-229°C)

Appearance: Rich brown color, some oil on surface

Flavor Profile:

- Diminished acidity

- Fuller body

- Bittersweet chocolate notes

- Deeper caramelization flavors

- Some spice notes may emerge

Best For: Espresso, moka pot, and pressure brewing methods

Dark Roasts (French, Italian, Spanish)

Ending Temperature: Well into second crack (445-465°F/229-240°C)

Appearance: Dark brown to nearly black, oily surface

Flavor Profile:

- Low acidity

- Heavy body

- Pronounced bitterness

- Smoky, roasty flavors dominate

- Origin characteristics largely obscured

- Lower caffeine content

Best For: Traditional espresso blends, cold brew, milk-based drinks

The Art of Roast Profiling

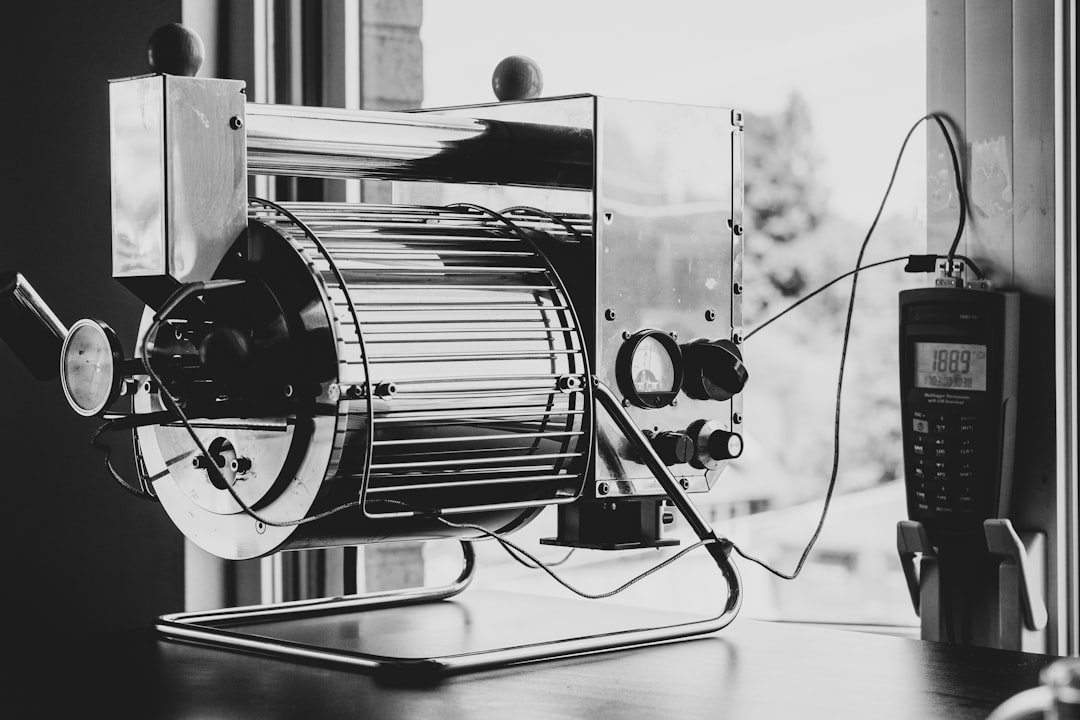

Beyond simply determining how dark to roast, professional roasters create detailed "profiles" that specify exactly how the temperature should change throughout the roasting process. This involves careful manipulation of:

- Charge temperature: The initial temperature of the roaster drum

- Rate of rise (RoR): How quickly the bean temperature increases

- Heat application: When to add or reduce heat

- Airflow: Controlling oxygen and smoke levels

- Development time ratio: The percentage of time spent after first crack

These factors can be manipulated to emphasize different characteristics even within the same roast level category. For example, two medium roasts might have very different flavor profiles based on how quickly they reached first crack and how long they developed afterward.

Roasting for Different Origins

Different coffee origins often benefit from customized roast profiles:

- Ethiopian and Kenyan coffees: Often roasted lighter to preserve their intrinsic floral and fruit notes

- Colombian and Central American coffees: Versatile, but often medium-roasted to highlight their balanced sweetness and acidity

- Indonesian coffees: Their earthy, spicy characteristics can benefit from medium-dark roasting to enhance body and sweetness

- Brazilian coffees: Often work well in medium to dark roasts, highlighting their nutty, chocolatey characteristics

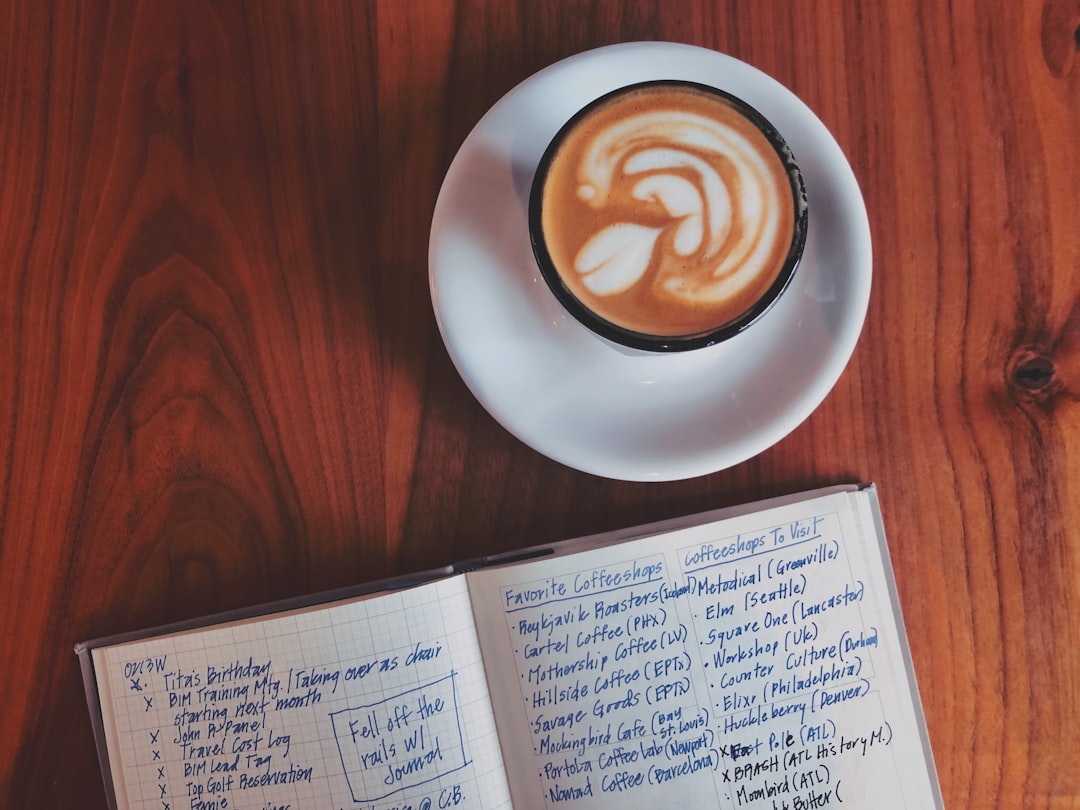

At GEO Coffee, we develop custom roast profiles for each origin we source, constantly fine-tuning our approach to bring out the best in every bean. Our roasters maintain detailed logs of each batch, allowing us to replicate successful profiles and continuously improve our craft.

The Future of Roasting

Coffee roasting continues to evolve with technology. Advanced roasters now use software that tracks temperature curves in real-time, allowing for unprecedented precision and consistency. Some roasters are experimenting with:

- Drum pressure manipulation

- Variable infrared heat application

- Algorithmic roast profile development

- Spectral analysis to evaluate roast levels

Despite these technological advances, the human element remains crucial. The sensory evaluation of the roasted coffee—cupping—is still the ultimate test of whether a roast profile has achieved its intended goals.

Understanding coffee roasting gives you a deeper appreciation for the craft behind your daily cup. Next time you try a new coffee, take a moment to consider the roaster's choices and how they've transformed those green seeds into the complex beverage in your cup.